Date Code Inspection

For many manufacturing operations the addition of an inkjet date or batch code is a vital part of the production process. The information coded onto the products often contains vital ‘Use By’, ‘Best Before’ and/or batch code information. In many cases this is a mandatory requirement before goods can be released into the supply chain where failure to code the correct information can lead to hefty fines from customers, product recalls and costly reworking.

Utilising the latest in smart camera technology from Datalogic we offer an extremely cost effective, compact and robust solution which verifies that all products contain the correct information by inspecting every date and batch code. The system is able to identify missing or incorrect information by using sophisticated ‘Pattern Match’ or ‘OCR’ tools to inspect 100% of the products as they travel through the production process. In the event of an error the units are able to operate reject mechanisms, stop conveyor lines and trigger warning beacons to highlight the fault to an operator.

P-SERIES SMART CAMERA

Features

- Extremely cost effective Smart Camera

- Built in Serial and Ethernet interfaces

- Wide variety of interchangeable lighting and lens options

- Built in digital inputs/outputs

- Powered by IMPACT software suite

- Very robust and compact IP67 rated housing

Vision Inspection Tools

- Pattern match detection

- Blob detection

- 1D/2D Barcode reading

- OCR text validation

- Multiple measurement tools

- Contrast measurement

IMPACT SOFTWARE SUITE

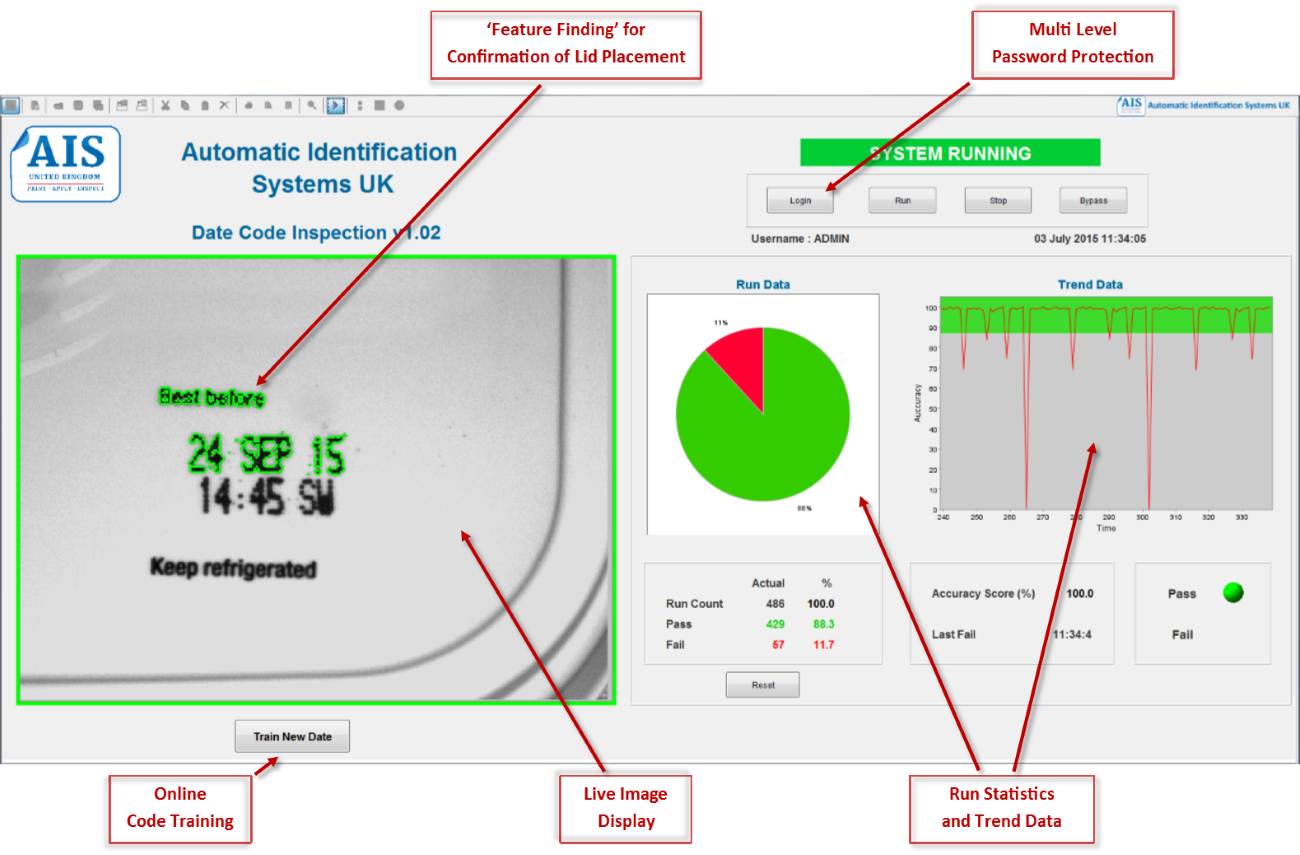

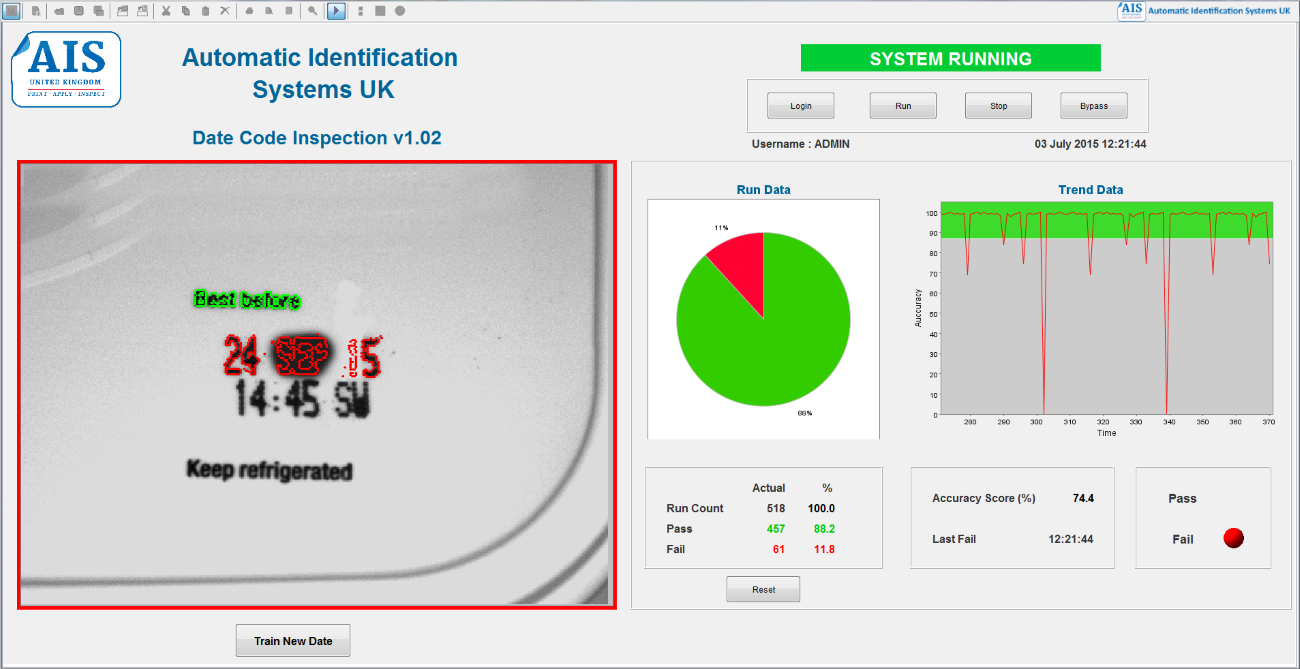

As a user interface we’ve created a base set of software tools that can be configured for any vision inspection application. For date and inkjet code inspection we use a combination of ‘Pattern Match’, ‘Blob’ and ‘OCR’ inspection tools that provide extremely robust inspection of multiple sectors. For each application the operator GUI can consist of either the ‘out of the box’ solution as shown below or can be customised to suit that particular application. Multi-level password protection is included and detailed run statistics are logged with an image of every fault stored for future reference. Trend data is also displayed that logs the quality of a code compared to the start of the production run which highlights any deterioration and pre-empts a failure.

The simple and intuitive operator display provides single-click training of new date codes and multi-level password protection. Clear, real-time statistical information is displayed along with a live image of every product. Images of faulty products are captured and stored for further analysis.

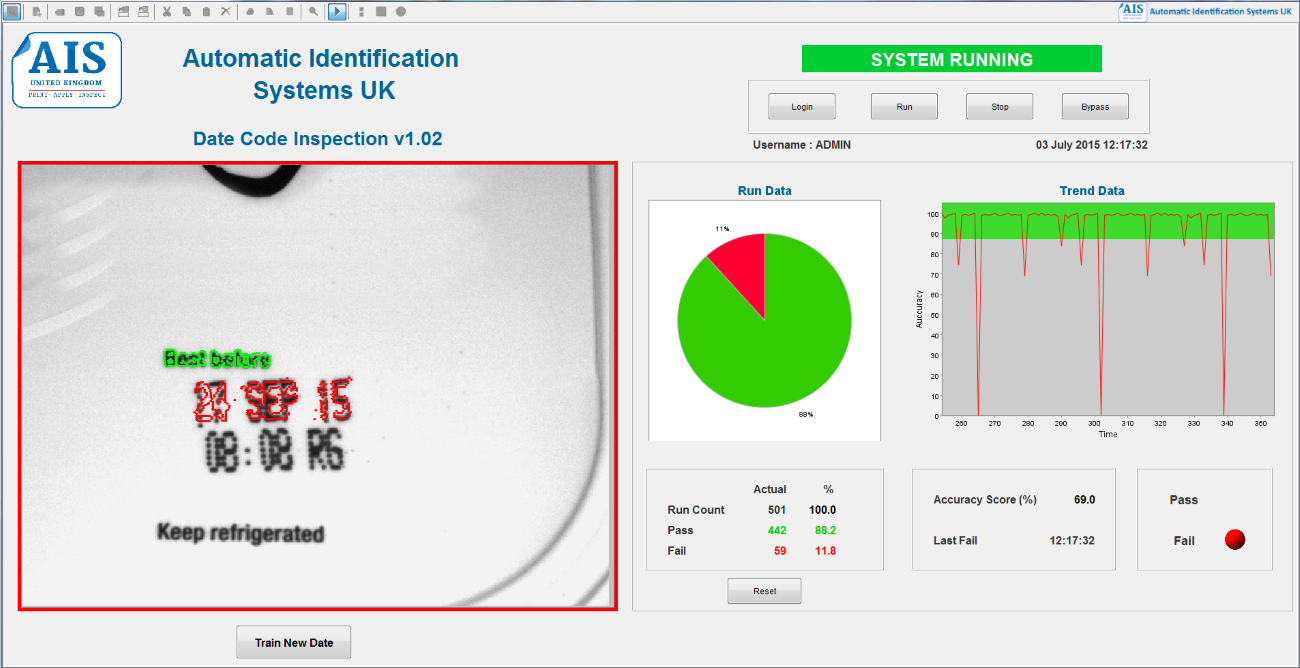

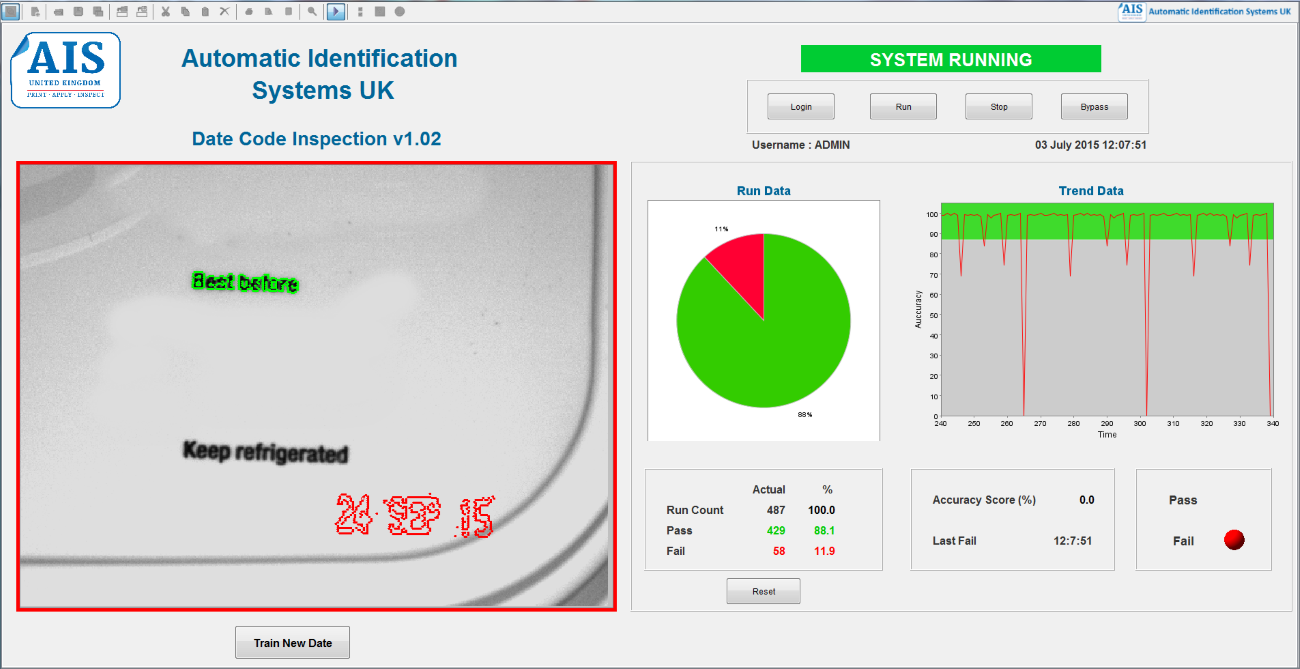

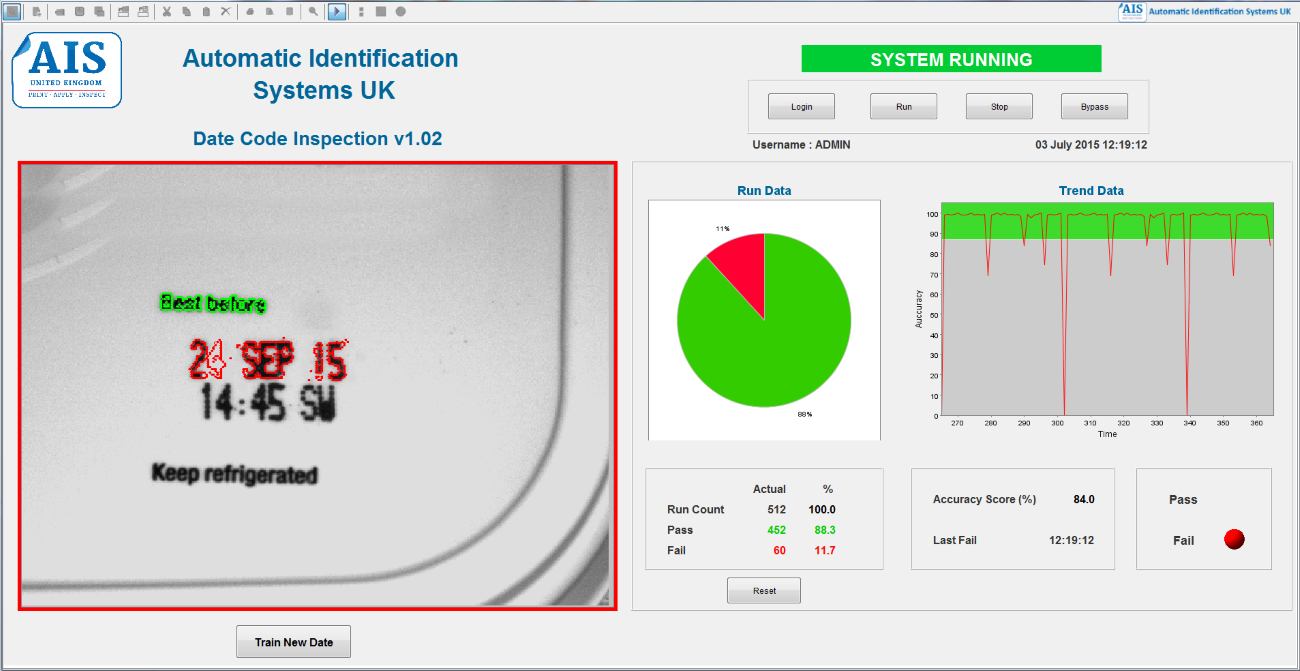

Using either ‘Pattern Match’ or ‘OCR’ inspection tools the P-Series camera is able to identify incorrect dates and batch codes.

The ‘Blob’ detection tool confirms the presence and position of the code within pre-defined tolerances.

Downloads

Video