LVS® 7500 Integrated Label Inspection System

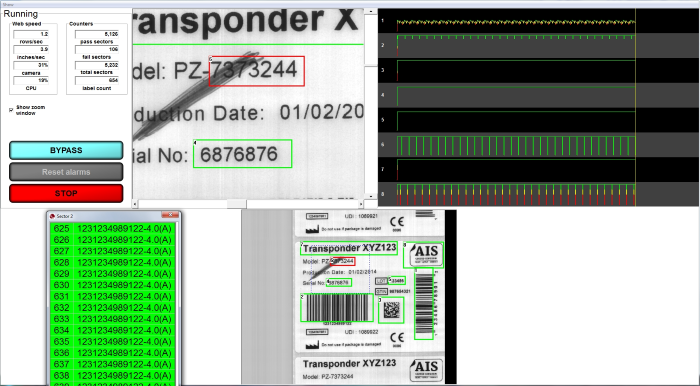

The sophisticated software supplied with the system is able to verify 1D and 2D barcodes to ISO/ANSI standards, uses OCR/OCV technology to analyse text fields and identifies blemishes caused by ribbon crease and damaged print heads. Multiple sectors can be analysed on each label with a minimum passing score being entered for each. If this passing score is not reached, the unit triggers an alarm and output that can be used to pause or stop the printer.

A record of every job and every error including an image of the faulty field is stored locally providing a full audit trail and run reports that can be recalled at a later date.

- The LVS® 7500 provides full ISO/ANSI barcode verification of 1D and 2D codes.

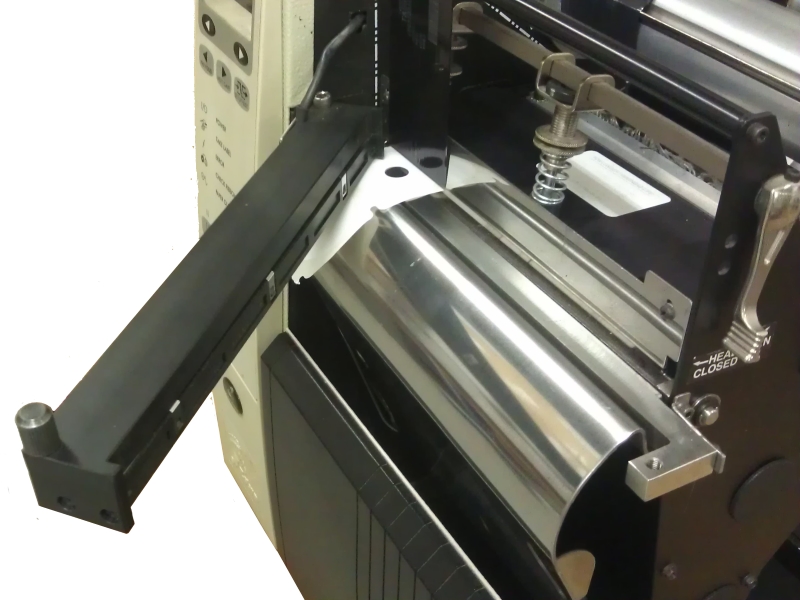

- When integrated into a thermal printer, the 7500 allows ‘last label out’ inspection and on demand printing.

- Multiple barcodes can be verified in both ladder and picket fence orientation.

- The LVS® 7500 inspects all nine ISO/ANSI parameters plus added features of determining blemishes, opacity, and human readable validation.

- Serialisation checks can be performed by validating the data in both barcode and human readable fields and highlighting any duplication.

- The LVS remote control feature allows the system to be controlled by external software allowing seamless integration into existing systems.

- The LVS® 7500 is the most reliable in-line barcode verifier and label inspection unit on the market and the only one able to verify 1D and 2D barcodes.

- OCR (Optical Character Recognition) and OCV (Optical Character Verification) inspection provide validation/verification on multiple text fields simultaneously.

- Blemish detection with variable tolerances and zoned areas allows the detection of print defects such as ribbon crease and printhead wear.

- Multiple barcode symbologies are supported including any combination of Linear, 2D and Stacked Linear codes all of which can be verified on one label within the field of view.

- The LVS® 7500 is 21-CFR Part 11 compliant ready so ideal for use in the pharmaceutical and medical device industries.