The Matrix 300N™ Barcode Reader

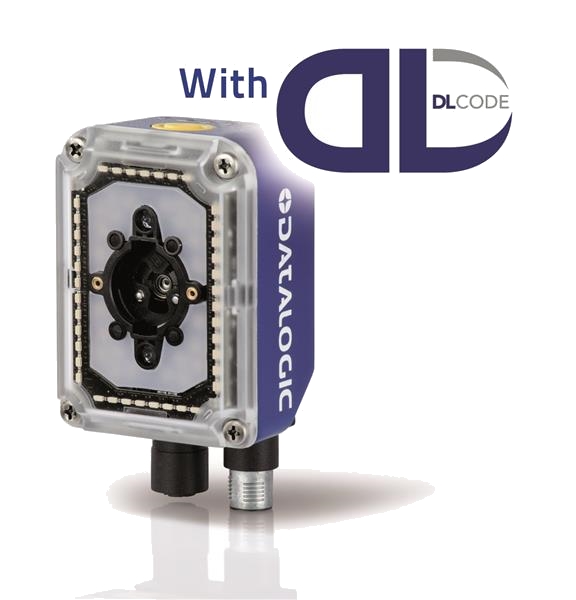

The optical system incorporates a liquid lens module for electronic focus control. As a result the reader offers automatic focus adjustment without the addition of moving parts. The integrated illuminator is embedded over the entire front surface of the reader. This innovative design allows for bright and uniform illumination of the barcode. The lighting design uses both bright field and dark field patterns resulting in optimal illumination on normal, etched, highly reflective or textured surfaces.

300N™ offers cost-effective communication options with Power over Ethernet (POE) connectivity through a standard Ethernet connection. The next generation imager is also built with on-board PROFINET-IO and Ethernet I/P, eliminating the need for external communication boxes or converters for increased flexibility and cost effectiveness.

Features

- All 1D and 2D barcodes supported

- Ultra-compact reader, rotating connector system

- Profinet-IO communication embedded

- Both manual and electronic focus control option

- Integrated dual illuminator: dark field/bright field

- Fast and high resolution image sensor: 1.3 megapixels, ‘true’ 60 frame/s

- Packtrack 2D for short object gapping

- Power over Ethernet Option

- Extreme Industrial grade: IP67, 0-50°C operating temperature

- Precise dual laser aiming system

Applications

- DPM code validation after marking

- Work-in-progress control

- Parts and assemblies traceability

- High speed process control

- End-of-Line traceability

- Reusable totes identification

- Medical device traceability

- Biomedical analysis machines

- Specimen collection machines